Norway Is Opening for Business in Carbon Capture

August 13, 2018 - The Norwegian Ministry of Petroleum and Energy has announced that it will be moving forward with an undersea project for carbon capture and storage (CSS), the first in the world to be able to store carbon dioxide (CO2) waste from multiple industrial sources. If the project is successful, it will serve as a stepping stone for full scale international operations.

The impetus behind this is to get ahead of the carbon capture curve and create an economically viable value chain solution for CCS. When this infrastructure is put into place, Norway will be able to import CO2 for permanent storage, providing a ready mechanism for countries and companies to set up their own CCS operations. It will also lower the threshold for a European hydrogen market. Norway could be getting into the business of importing and sequestering CO2 as a service.

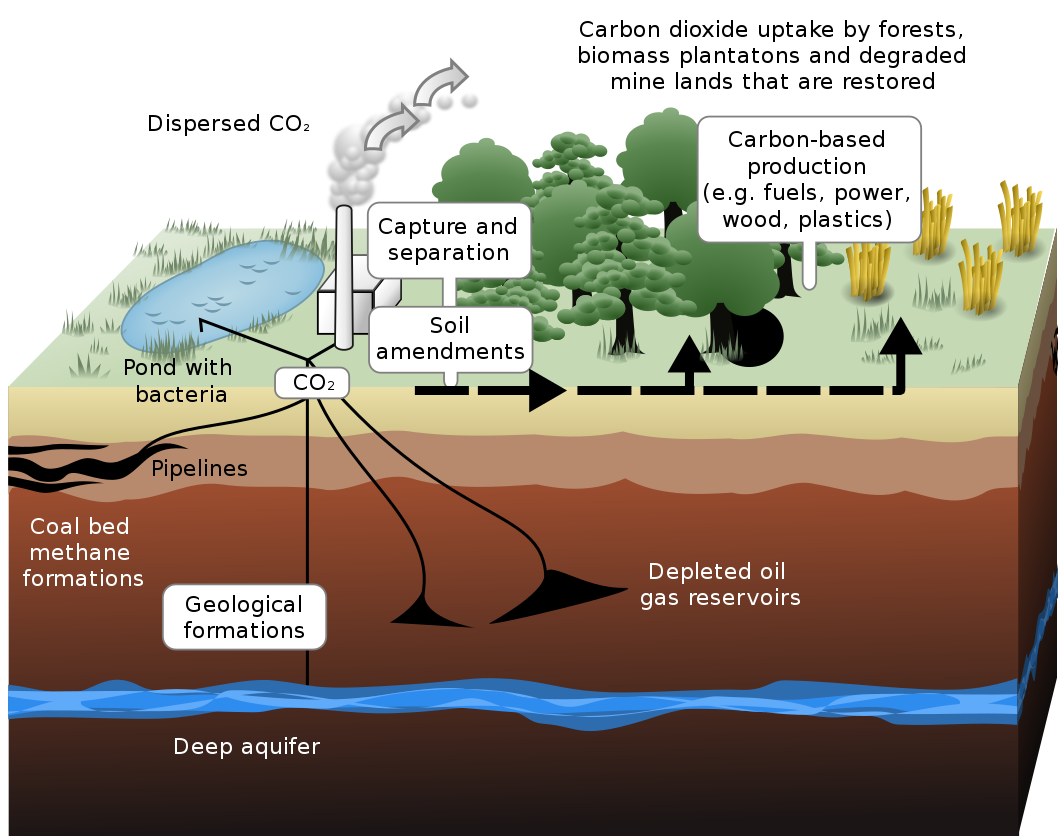

This schematic shows terrestrial and geological sequestration of carbon dioxide emissions from a coal-fired plant.

Image source: LeJean Hardin and Jamie Paynederivative work: Jarl Arntzen [CC BY-SA 3.0 (https://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

The country is already the world leader in carbon storage, going back to the Sleipner Project, which has stored one million tons of CO2 per year since it began about 20 years ago. It was the first facility dedicated to CO2 storage and was installed as a means of avoiding the Norwegian carbon tax and reducing the CO2 content of natural gas produced in the area, which exceeded the specified European Union limit in CO2 concentration of 2.5%.

The CO2 was removed using an amine-based sorbent, with the excess being pumped under the seabed to a depth of roughly 1 km. Of the 17 large-scale CCS facilities operating worldwide today, only four are dedicated to carbon storage. Two are in Norway (Sleipner and Snøhvit), one in Canada (Quest), and one in the US (Decatur). The rest are being used for enhanced oil recovery.

The importance of CCS technology is hard to overstate, at least for as long as fossil fuels are part of the energy and industrial landscape. The International Energy Agency (IEA) has called CCS a key technology for reducing coal and gas emissions across industries. In a statement to Business Insider, an IEA spokesperson said, “There is no other technology solution [today] that can significantly reduce emissions from the coal and gas power generation capacity that will remain a feature of the electricity mix for the foreseeable future. No other technology solution is capable of delivering the deep emissions reductions needed across key industrial processes, such as steel, cement, and chemicals manufacturing, all of which will remain vital building blocks of modern society.”

This latest demonstration scale project, which is expected to be online by 2020, is unique in that it will capture emission from two different industry types: a cement factory in Brevik, owned by Heidelberg Cement, and an energy recovery (waste incineration) plant in Oslo. These sites all delivered their concept studies for CO2 capture in the fall of 2017. Each plant plans to capture roughly 400,000 tons annually.

In operation, CO2 will be transported by ship from each capture plant to an onshore facility on the Norwegian West Coast for temporary storage. It will then be transported via a pipeline to a subsea formation in the North Sea for long-term storage. The Norwegian Ministry of Petroleum and Energy has identified several injection wells east of the Troll field on the Norwegian Continental Shelf. The CO2 will be stored permanently up to 2,000 meters below the seabed.

According to Equinor, an oil and gas company that is a partner in the project and was involved in the earlier Norwegian CCS projects, “The reservoir surveyed for CO2 storage has the capacity to accommodate significant additional volumes.”

The company will be responsible for the planning of the storage facility and is also looking into the feasibility of pairing this carbon capture capability with hydrogen production. When hydrogen is produced from natural gas, it emits CO2 as a byproduct. But if the CO2 could be safely sequestered, it could provide a carbon-free alternative. Equinor, along with partners Vattenfall and Gasunie, is currently assessing the possibility of converting a natural gas power plant to run on hydrogen and sequestering the resulting CO2 emissions beneath the seabed.

RP Siegel, PE, has a master's degree in mechanical engineering and worked for 20 years in R&D at Xerox Corp. An inventor with 50 patents, and now a full-time writer, RP finds his primary interest at the intersection of technology and society. His work has appeared in multiple consumer and industry outlets, and he also co-authored the eco-thriller Vapor Trails.