$80 Million Arq Plant in Kentucky Unveiled

By Trent Knuckles

April 11, 2019 - A patented process that allows coal waste to be recovered and turned into and relatively clean, high-value energy source is the impetus behind the construction of an $80 million facility in Corbin that will employ about 70 workers in the very near future.

C.K. Lane, Head of U.S. Operations for a startup energy company called Arq, revealed details about the project during the Southern Kentucky Chamber of Commerce monthly luncheon, held at The Corbin Center Tuesday.

C.K. Lane, Head of U.S. Operations for Arq, spoke to at the Southern Kentucky Chamber of Commerce luncheon Tuesday.

Arq, which is based in London, England, is betting big on the potential of the first-of-it’s-kind facility in Corbin.

“Why Corbin?” Lane asked, rhetorically of the large audience who attended to hear him speak.

“Back in the 1950s, U.S. Steel built the largest coal preparation plant in the United States here in Corbin,” Lane explained. “All the waste is deposited here in Corbin. There’s about 41 billion tons of refuge on the Corbin site. About 16.5 billion tons are the fines which is what we will be processing.”

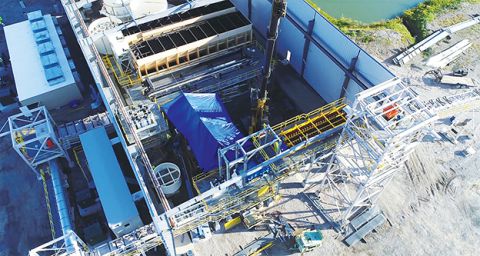

The facility is currently being completed on the old US Steel site behind CSX. Lane said the coal waste, or “fines” as he referred to it, would be dredged from large slurry ponds on the site. With what’s there now, the Corbin facility could operate for over 30 years. He’s hoping to commission the plant in June or July to start initial production.

Full production is expected around December of this year, or January 2020.

“We will be running 24 hours a day, seven days a week,” Lanes said. “The resource is there. We’ve got a very good supply of resource.”

The $80 million coal waste processing facility, located at the old US Steel property in Corbin, is planned to be commissioned by June or July.

The main facility is housed in a structure that is 460 feet long, 110 feet wide and 45 feet high. Inside is “very expensive” equipment that Lane said has never really been used before to process coal, but instead is ubiquitous in the pharmaceutical and food processing industries.

Lane explained that, in essence, the process to extract energy from the coal waste consists of reclaiming the material from slurry ponds, and through steps of separating, grinding and drying, turning it into what will be known as “Arq fuel.”

“It’s very low cost. We can do it for about $11 a barrel,” Lane explained.

Oil traditionally costs $40 to $50 a barrel to produce.

Key to the process is something called “micro-sizing” — grinding down the coal fines into a 99 percent pure, ultra-fine hydrocarbon powder about 3 microns in size. By comparison, a human hair is about 100 microns.

“It’s thinner than toner cartridge in your copy machine,” Lane said.

“It’s so hard to imagine how thin these particles are. If you put a black particle on the end of your finger, you can’t really see it.”

The substance, Lane said, is valuable to oil companies because it can be blended with oil to bring the average cost of producing oil down, but still burns and acts like oil because it remains suspended in it. Also, it burns relatively clean since it has very little sulfur.

Worldwide, Lanes said there is about 50 billion tons of coal refuge that can be accessed, equivalent to about 120 billion barrels of oil.

“120 million barrels would supply the US for about 17 to 18 years at current consumption,” Lane said. “That’s energy sitting out there that we are trying to capture.”

Arq fuel would be targeted for use in the marine industry, Lane said — cruise ships and cargo vessels, etc. Also, it could be used as a fuel oil, popular as a power source, particularly in Caribbean nations.

Bruce Carpenter, Economic Development Director for the city of Corbin, said he’s been working closely with the company since 2015, and that Tuesday’s announcement of the project was the result of a lot of effort, and significant investment by the company.

“This is the sort of project that can really have a long-term, positive economic impact on our community,” Carpenter said. “These will be good jobs that families can thrive on. Corbin is lucky to have Arq as one of its newest corporate citizens.”

Carpenter added that the facility would represent the third international company to locate in Corbin in recent years. KOWA, a Japanese company, and Smartwood, a French company, are already operating in the nearby Southeast Kentucky Regional Business Park.

Kentucky Utilities recently completed construction on 10-megawatt substation just to supply power to Corbin’s Arq facility. It requires about 18,500 horsepower to run all the equipment in the plant.

Lane noted that one environmental benefit of Arq would be that it cleans up and reclaims sites that currently are full of coal waste. Also, he said Arq’s end product is a cleaner burning fuel than traditional coal or oil.

Arq is expanding rapidly with other facilities planned for construction in the United States, South Africa and Australia. The Corbin plant is considered the company’s first prototype facility.

Arq officials will be working with the Corbin Economic Development Agency and Carlisle Contracting in the coming months on hiring for the facility.

Numerous public officials attended Tuesday’s luncheon and expressed excitement about the project.

Corbin Mayor Suzie Razmus, who recently toured the facility, said she’s excited to see the site become a job generator for the area again.

“What a great day it is to see the former US Steel property in use again for the benefit of our community and our environment,” Razmus said. “It’s a very exciting project and I look forward to a positive and mutually beneficial relationship with Arq for many years to come.”

Knox County Judge-Executive Mike Mitchell praised Arq and said the facility will be a positive force for both the community and nation.

“Today’s presentation by C.K. Lane of Arq at the Southern Kentucky Chamber of Commerce meeting was exciting news for our region,” he said. “The innovation and technology to extract renewable resources from disposed coal fines into energy to enhance our country’s energy market will benefit our nation and local economy. I look forward to working with this company.”