US Hard at Work for Viable Solutions to Rare Earth Elements's Extraction

By Anna Domanska

March 2, 2020 - Rare earth elements have become a weapon of bargain in trade wars for China, which produces almost 80 percent of these minerals that are primarily used in all modern-day devices like smartphones, electric vehicles, satellites, batteries and more.

Rare earth elements are known as the vitamins of chemistry, as a mere dose of these elements in hi-tech devices improves productivity and efficiency.

If China turns off this supply of minerals, then the world would likely suffer and have to look for alternative sources. But experts and commodity traders are of the opinion that it would not be such a calamity as these rare elements are not so rare and can be found in Brazil, Canada, Australia, and the United States.

Rare earth elements are a by-product of mining and extraction is a costly and difficult task. The current research on extraction methods is concentrating on coal and coal by-products like coal ash, refuse rocks from mines, and acid mine drainage treatment sludge.

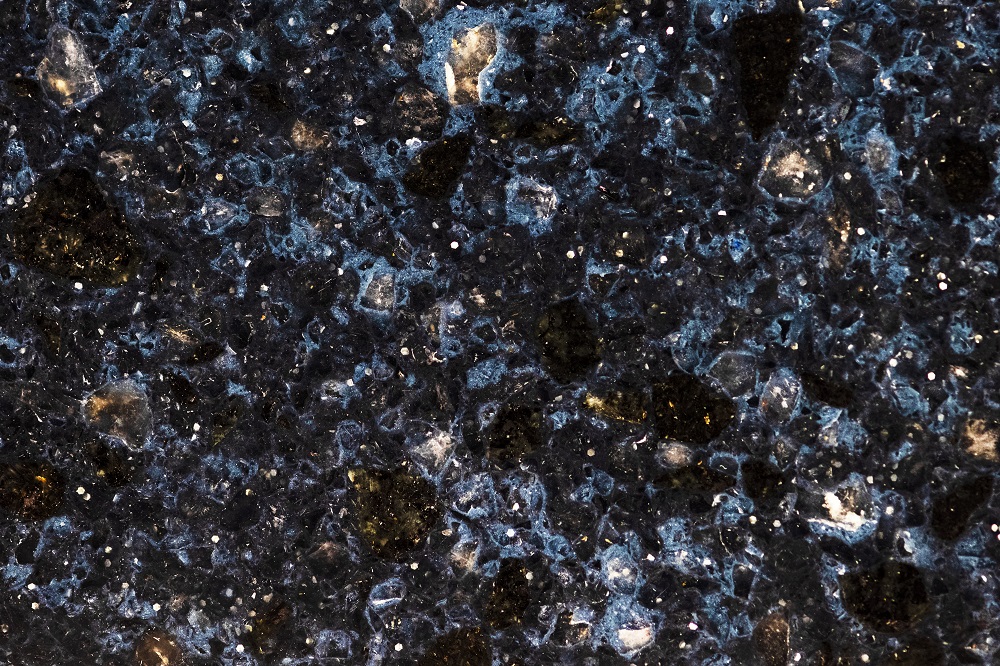

Rare earths are a group of 17 elements and are “moderately abundant. Some of these elements are cerium holmium, thulium, ytterbium, yttrium and neodymium. They are often found mixed with other minerals like thorium and sometimes in uranium.

The current research on extraction methods is concentrating on coal and coal by-products like coal ash, refuse rocks from mines, and acid mine drainage treatment sludge.

The reason they are called rare is that they are not found in concentration, and their extraction process is expensive and ecologically unsustainable with the current methods.

The whole process involves a series of acid baths and even radiation that is highly costly, environmentally not sustainable and also labor intensive. China has all the advantages of labor and already existing mines that have these rare elements as a by-product. The environmental laws are also a little lenient here compared to the U.S.

The Department of Energy (DOE) and the defence forces are ready to invest millions of dollars in projects to develop sustainable domestic sources from coal and coal waste products.

Some projects in the pipeline are:

American chemical firm Blue Line Corp and Australian rare earth miner Lynas are already in talks to set up new production facilities in the U.S. with the help of defence funding.

Rare earth elements have become a weapon of bargain in trade wars for China, which produces almost 80 percent of these minerals that are primarily used in all modern-day devices like smartphones, electric vehicles, satellites, batteries and more.

Rick Honaker, a mining engineering professor, and his research team at the University of Kentucky are trying to extract rare earths from refuse rocks.

Paul Ziemkiewicz, director of the West Virginia Water Research Institute at West Virginia University, is also working on a project to extract valuable rare earths from acid mine drainage sludge. Dr Zeimkiwwicz has been granted $5 million from the DoE to work on acid mine drainage sludge and come up with a scalable pilot project. If it works, Dr. Ziemkiewicz estimates the acid mine drainage in West Virginia, Pennsylvania, Maryland, and Ohio alone could yield annually up to 2,200 tons of rare-earth elements, more than three times what the U.S. produced in one year. The nation has up to 500,000 abandoned mines.

Prakash Joshi, manager of advanced systems technologies at Massachusetts-based Physical Sciences, is heading a DOE-funded project with the Kentucky-based Center for Applied Energy Research and Pennsylvania-based Winner Water Services, to develop a pilot-scale plant that produce rare-earth concentrates from coal ash.

The U.S. dominated rare earth extraction until China took the lead in the 1980s. America’s Montana Pass Mines, which were shut down, have still got their facilities intact and all ready for production. Dr. Ziemkiewicz estimates the acid mine drainage in West Virginia, Pennsylvania, Maryland, and Ohio alone could yield annually up to 2,200 tons of rare-earth elements, more than three times what the U.S. produced last year. The nation has over 500,000 abandoned mines. The Montana Pass Mines, which were shut down, have the capacity to produce one-tenth of the US’ rare earth needs.

“Our advantage with AMD [acid mine drainage] is that 45 to 50% of the rare earths present are heavy rare earths,” typically the most valuable, Dr. Ziemkiewicz says.

Mining companies are responsible for cleaning all the acidic drainage that is deposited in the nearby streams and water sources. If a viable rare earth extraction method is invented, then the mining companies can use the rare earth sales to fund the very expensive cleaning processes.