Decisions. Decisions. Should I use Mechanical Fasteners or a Vulcanized Splice?

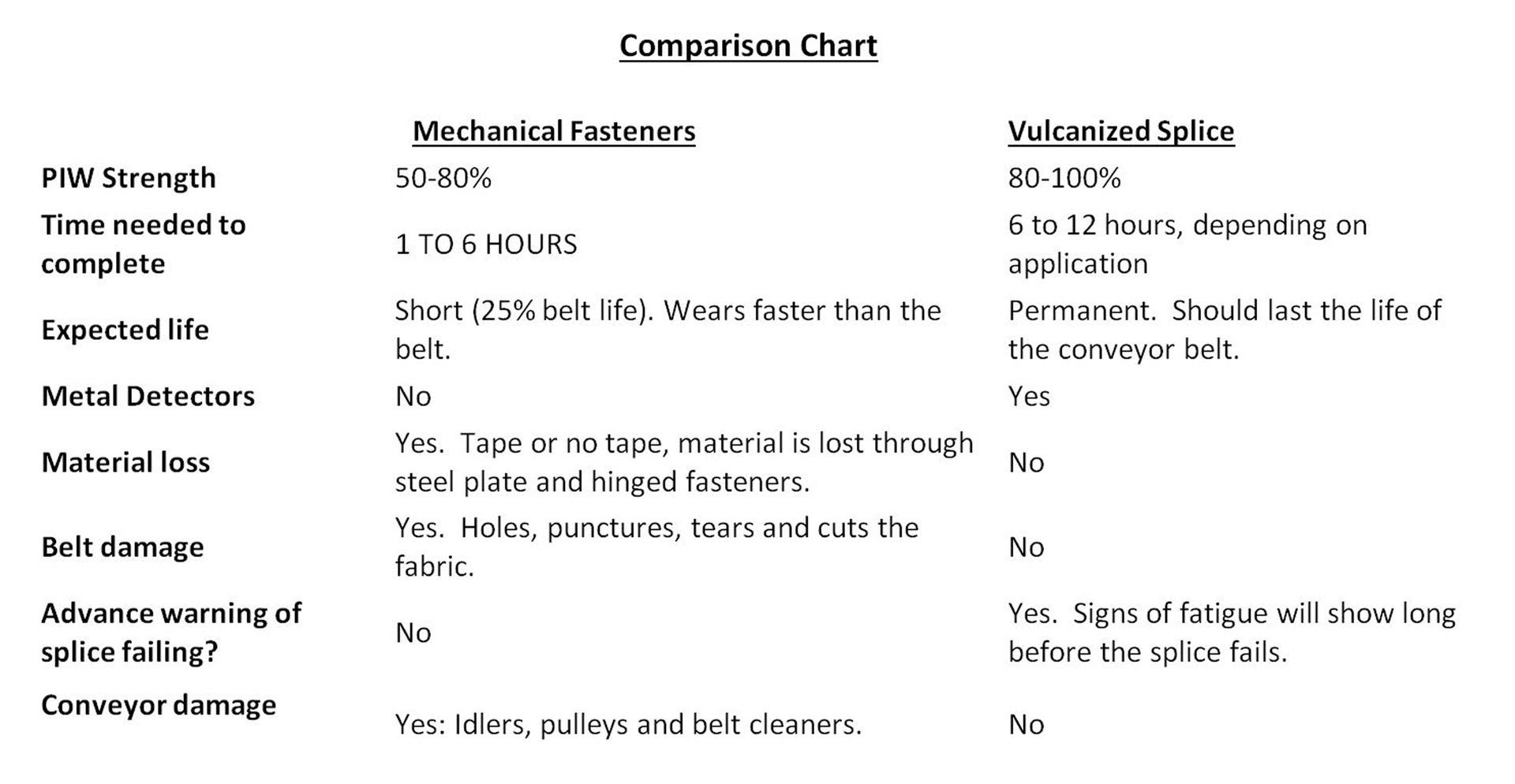

May 13, 2020 - Conveyors are one of the key components to making any coal facility run efficiently and successfully. As we all measure ourselves and try to improve our Total Cost of Ownership (TCO), the decisions we make to maintain our plants are critical to improving these metrics. When it comes to the critical issue of belt splicing, there are two primary options to consider: Mechanical fasteners or a hot vulcanized splice.

A mechanical fastener is a fastening system that uses steel /metal hinges or plates, that are installed using bolts, rivets, screws or a series of staples to fasten or attach the fastener to the conveyor belt.

While one of the main benefits of a mechanical fastener is the low cost to install, the downside of mechanical fasteners is the entire load / burden is on a very small portion of the belt. The methods to installing these different types of fasteners involve cutting or tearing the belt’s fabric to install the fastener through the belts’ carcass. This alone causes the splice to be weaker than the rest of the conveyor belt.

When a conveyor belt “runs-off” due to mistracking, misalignment or some other unforeseen reason, the odds that the mechanical splice will either get “hung-up” or “pulled-out” or a side of your conveyor belt gets ripped off are pretty high. Also the constant banging of the mechanical fasteners over the idlers, pulleys and belt cleaners will not only drive your ear drums crazy, but also cause premature wear on all the components they come into contact with.

A hot vulcanized splice is the process of chemically bonding two conveyor belt ends together through the application of uniform heat and pressure. A conventional fabric belt splice consists of two belt ends stepped down and overlapped together. The ends are shaped like matching ends of shallow steps, making a “seam-less” style splice.

The primary advantage of a vulcanized splice are that the hot vulcanized splice is nearly as strong as the original belt, which results in longer conveyor belt life and, because of that increase in reliability, conveyor belt downtime is reduced. The long term Strength and Durability of a vulcanized splice is unmatched by any type of mechanical fastener.

What are some of the other benefits of a vulcanized splice?

-

Cleaner. A vulcanized splice is smooth as the top cover of the conveyor belt itself. By having a completely smooth top cover, without metal fasteners helps provide a better sealing and wont prematurely wear your skirting in the load zone areas. Vulcanized splices are much “friendlier” to belt cleaners, as a vulcanized splice won’t damage your belt cleaner blades, which will help the belt cleaners do a better job at cleaning the conveyor belt, reducing carry-back.

-

Quieter. Hot vulcanized splices don’t have any metal in them and therefore the splice is as quiet running as the rest of the belt.

-

More efficient. A vulcanized splice allows the conveyor belt to wrap around smaller diameter pulleys than a mechanical fastener.

In summary, there are a number of advantages of a vulcanized splice verses a mechanical fastener. The hot vulcanized splice has more strength, less tracking issues, less spillage and less carryback problems. Because of that, the conveyor belt and conveyor components will have a longer useful life as a valuable asset to you and your company.

(1).jpg)