New NETL Catalytic Process Makes High-Quality Graphite from Coal Waste Products

December 4, 2024 - NETL’s research has unlocked a low-temperature synthesis process to make America’s coal waste into critical mineral graphite with a lower processing intensity. This takes what would otherwise be an environmental liability and instead use it to help address rising demand by adding to the domestic supply chain and address commercial market needs for several key industries as well.

The novel process developed by researchers at NETL focuses on using earth-abundant catalyst materials, such as iron, to facilitate the production of highly crystalline graphite. Coal of different ranks, coal waste, coal char, bio-char and plastic waste have been demonstrated to work as feedstocks with this process.

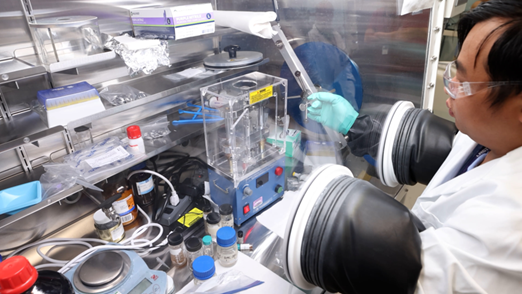

NETL’s Ngoc Tien Huynh uses coal waste derived graphite to make a lithium-ion battery for performance testing.

However, the new catalyst from NETL results in a manufacturing process that is not only quicker than conventional catalytic processes, but also requires less heat, and therefore uses less energy and costs less for users to operate.

The NETL catalyst is responsible for dropping process temperatures from 3,000°C down to less than 1,500°C and reducing process times from several weeks to just a few hours.

Additionally, research demonstrates the catalyst can be recovered, recycled and reused indefinitely, which improves the overall economics of graphite production. For example, battery anodes using graphite produced with the NETL-developed catalytic process perform as well as anodes made with commercial graphite.

“The low-temperature synthesis of graphite from coal and coal waste could lead to a new cost-effective domestic industrial manufacturing base for this critical material, boosting the sustainable energy sector and preserving the environment for future generations,” said Ki-Joong Kim, research scientist in the Materials Engineering and Manufacturing Division of NETL and principal investigator of the Lab’s catalytic process. “What’s more, because the Lab’s catalytic process results in product faster and cheaper, it also leaves a lighter environmental footprint. This could be a splendid asset in the toolbox of the American economy, as new graphite sources and production methods are needed now more than ever.”

Graphite is classified as a critical mineral in the United States because of its use in essential manufacturing combined with the limitations caused by its offshore supply chain. Graphite has a central role for renewable and low-carbon energy technologies, where it is used in anodes for lithium-ion batteries, high-strength composites for wind and wave turbines and high-strength composites for fly wheel energy storage.

Roughly one-third of the global market is supplied using natural graphite, with the remaining two-thirds being supplied by synthetic graphite. Global production of both natural graphite and synthetic graphite is concentrated in China. China currently produces more than two-thirds of the world’s natural graphite (71% of world production in 2019) and more than half of the world’s synthetic graphite (2.07 million metric tons of synthetic graphite was produced in 2019, with China producing more than 58% of that). Natural graphite has not been mined in the United States since 1990, while synthetic graphite production continues to grow.

Low-temperature synthesis of graphite from inexpensive waste from America’s coal industries could lead to a new cost-effective domestic industrial manufacturing base for this critical material, boosting the sustainable energy sector and preserving the environment for future generations.

NETL is a U.S. Department of Energy national laboratory that drives innovation and delivers solutions for a clean and secure energy future. By leveraging its highly skilled innovators and state-of-the-art research facilities, NETL is advancing carbon management and resource sustainability technologies to enable environmental sustainability for all Americans.